MODULE 2:

Generating

Ideas Through

Processes

In this module, I will explore digital fabrication and parametric software through two tasks.

Key Concept:

The main concept of my design is to generate a space with legible circulation paths inside, both blurry and clear

thresholds, the interaction between people in the interior and exterior spaces. Use parametric operations to form

both curved and straight circulation paths by regularly or randomly arranging and transforming simple geometries

and try to make different senses of the depth of the space by focusing on positive and negative space and people’s

view at the same time.

Task a

SUBTRACTIVE & ADDITIVE PROCESSES

In Task A, I was supposed to explore volumes and 3D printing techniques with a focus on additive and subtractive processes. The parametric software Grasshopper was introduced. I was going to make iterations of geometries by using 3 main techniques including "Growth", "Point Attractor" and "Curve Conditions" in Grasshopper. Then try to find 3 key iterations which approach my concept.

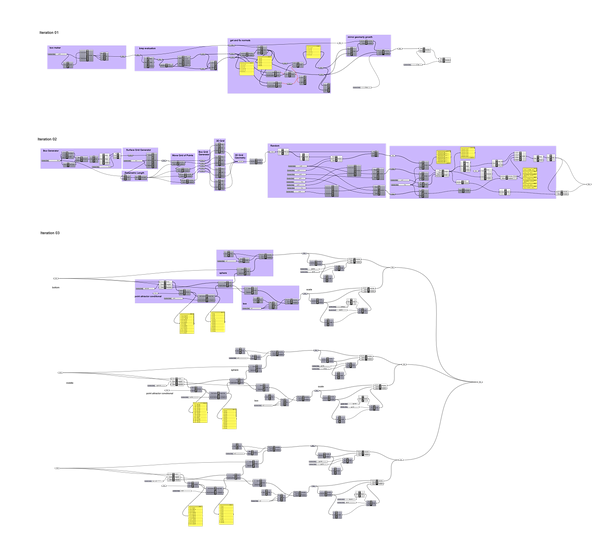

GrassHopper Script:

I was trying to make circulation paths in three different ways during the scripting. Firstly I

tried to make the cubes grow regularly and add some random and irregular elements

to find interesting outcomes. Secondly, I tried the method of conditionals to make some

legible tunnels for circulation. Lastly, I was trying to make some special geometries like

pyramids and crystal structures with random dimensions and positions to form some

more natural spaces and paths between them.

iteration Matrix:

The aim of my iterations is to find possibilities of different shapes of circulation paths and make larger space at the intersections to combine motion and stillness. I considered trying to make tunnels in different layers with different width in 3 different ways to achieve this. For a larger scale, tunnels provide paths for people not just to pass through but also look through. The connecting points of tunnels can also form larger spaces where circulation paths converge for people to gather and also bring a sense of depth.

The first one on the left is made by the subtractive

process, resulting from iterations using the technique of “growth”, which provides a great sense

of depth and space with different sizes. It also has

a polyporous structure that defines some straight

circulation paths and “skylights” for sunlight to

pass through. The iteration process of this part is a process to approach the balance of regularly distributed and randomly distributed basic geometries and try to find a structure with a clear threshold and interaction between interior spaces and exterior space.

Key Iteration 1:

The second iteration in the middle is made by additive process from iterations using point attractor and randomly distributed geometries. In this part of the iterations, I was looking for some interesting shape of space enclosure. Firstly, the outcome should have a primary path for circulation.

Meanwhile, there should have some “windows” on the enclosure of spaces to support interaction between inside and outside. The chosen iteration achieves both features that I was looking for. Besides, it provides some private spaces at the corners where two diamond-shaped structures intersect.

Key Iteration 2:

The process of making the third chosen iteration

on the right has an obvious intention of fi nding

paths on different levels with different sizes and

the relationship between covered spaces and

open-air spaces. This iteration is chosen because

it has the most entrances and attractive railing

like structure, and its paths extend in all directions.

Key Iteration 3:

3D printing:

To create a 3D print file, the first step that I have done is to make

sure that each of the three models is integrated, i.e. there is no unconnected structure in models. Next, I transferred the solid polysurface into meshes in Rhino and exported it as an STL file for printing. Then, I checked the thickness of each part of my models to ensure that their edges were solid enough to be able to be print because 3D printing is constrained to generating sharp geometries.

The other problem that I faced is

the open mesh. I went back to the Rhino model and tried to fix it by using fewer polygons in meshes. In order to save support material and reduce the time consumption of the fabrication process, I tried to rotate the models to find a base that can reduce the mass of cantilevers.

space test:

Task b

SECTION & WAFFLE STRUCTURES

In Task B, I will explore surfaces and laser cutting techniques, and apply two different techniques including "XY Waffle" and "Radial Waffle" to two chosen iterations from Task A respectively.

grasshopper

scripts:

Laser cutting arrangement:

space test: